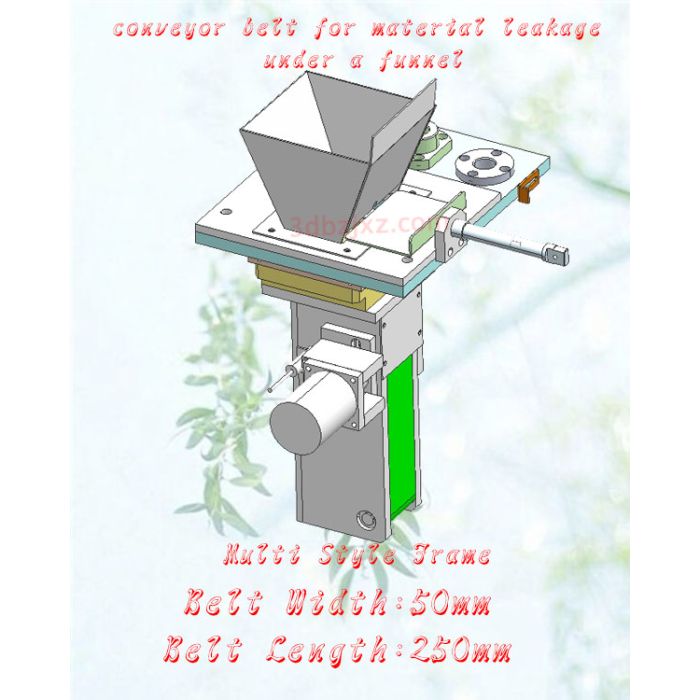

beltconveyor_w50_l250

- Stp samples download

- click to down

试用数据点击上方下载!

When designing a conveyor belt for material leakage under a funnel, multiple key factors need to be considered to ensure its effectiveness and safety. Here are some key design considerations:

Material characteristics:

Consider the general characteristics of the material leaking from the funnel, such as density, maximum particle size, flowability, presence of oil or chemicals, maximum temperature, and whether flame retardancy is required.

Select the appropriate conveyor belt material and cover rubber thickness based on the wear resistance of the material to ensure the durability of the conveyor belt.

Conveying capacity:

Determine the maximum conveying capacity required for the conveyor belt, which is the amount of material that needs to be conveyed per hour.

Calculate the bandwidth and belt speed of the conveyor belt based on its conveying capacity to ensure that materials can pass smoothly through the conveyor belt without blockage or overflow.

Bandwidth and speed:

The bandwidth should be calculated based on factors such as material particle size, stacking angle, and conveying capacity to avoid waste caused by excessive bandwidth or material scattering caused by narrow bandwidth.

The selection of belt speed should take into account factors such as material fluidity, conveying distance, inclination angle of the conveyor, and unloading method. Generally speaking, longer and horizontal conveyors can choose higher belt speeds, and the larger the inclination angle or the shorter the length, the lower the belt speed should be.

Conveyor belt structure:

Choose a suitable conveyor belt structure, such as flat conveyor belt, groove conveyor belt, or tubular conveyor belt, to meet the specific needs of material leakage below the funnel.

For conveyor belts that are prone to material leakage, accessories such as bottom lining rubber plates, sealing plates, or adjustable guide hoppers can be installed at the bottom of the conveyor belt to prevent material leakage from the bottom of the conveyor belt.

Conveyor route layout:

Determine the route layout of the conveyor based on the position and conveying direction of the funnel, including the distance between the head and tail rollers of the conveyor, the height of lifting or lowering, and the inclination angle of the conveyor.

Ensure that the route layout of the conveyor is reasonable to avoid problems such as material accumulation, blockage, or wear during transportation.

Safety and Protection:

When designing, safety measures for conveyor belts should be considered, such as installing protective covers, emergency stop buttons, etc., to ensure the safety of operators.

For high-temperature or flammable materials, conveyor belts with high temperature resistance or flame retardant properties should be selected, and corresponding fire prevention measures should be taken.

Maintenance and upkeep:

When designing, consideration should be given to the convenience of maintenance and upkeep of the conveyor belt, such as easy replacement, cleaning, and lubrication.

Provide necessary maintenance tools and spare parts to ensure the long-term stable operation of the conveyor belt.

In summary, when designing a conveyor belt for material leakage under a funnel, it is necessary to comprehensively consider multiple factors such as material characteristics, conveying capacity, belt width and speed, conveyor belt structure, conveyor route layout, safety and protection, as well as maintenance and upkeep. By reasonable design and selection, the effectiveness and safety of the conveyor belt can be ensured to meet production needs.

在设计用于漏斗下方漏料的输送带时,需要考虑多个关键因素以确保其有效性和安全性。以下是一些主要的设计注意事项:

-

物料特性:

- 考虑漏斗中漏下的物料的一般特性,如密度、最大粒度、流动性、是否有油或化学药品、最高温度以及是否需要阻燃等。

- 根据物料的磨损性选择合适的输送带材质和覆盖胶厚度,以确保输送带的耐用性。

-

输送能力:

- 确定输送带所需的最大输送能力,即每小时需要输送的物料量。

- 根据输送能力计算输送带的带宽和带速,确保物料能够顺畅地通过输送带而不发生堵塞或溢料。

-

带宽与带速:

- 带宽应根据物料的粒度、堆积角、输送量等因素进行计算,避免带宽过大造成浪费或带宽过窄导致物料撒落。

- 带速的选择应考虑到物料的流动性、输送距离、输送机的倾角以及卸料方式等因素。一般来说,较长及水平的输送机可选择较高带速,倾角越大或机长越短,带速应越低。

-

输送带结构:

- 选择合适的输送带结构,如平型输送带、槽型输送带或管状输送带等,以适应漏斗下方漏料的具体需求。

- 对于易漏料的输送带,可以在输送带的底部安装底衬胶板、密封板或可调节的导料斗等附件,以防止物料从输送带底部漏出。

-

输送机线路布置:

- 根据漏斗的位置和输送方向确定输送机的线路布置,包括输送机的头尾滚筒之间的距离、提升或下降的高度以及输送机的倾角等。

- 确保输送机的线路布置合理,避免物料在输送过程中发生堆积、堵塞或磨损等问题。

-

安全与防护:

- 设计时应考虑输送带的安全防护措施,如安装防护罩、紧急停机按钮等,以确保操作人员的安全。

- 对于高温或易燃物料,应选择具有耐高温或阻燃性能的输送带,并采取相应的防火措施。

-

维护与保养:

- 设计时应考虑输送带的维护和保养方便性,如易于更换输送带、清洁和润滑等。

- 提供必要的维护工具和备件,以确保输送带的长期稳定运行。

综上所述,设计用于漏斗下方漏料的输送带时,需要综合考虑物料特性、输送能力、带宽与带速、输送带结构、输送机线路布置、安全与防护以及维护与保养等多个因素。通过合理的设计和选择,可以确保输送带的有效性和安全性,满足生产需求。