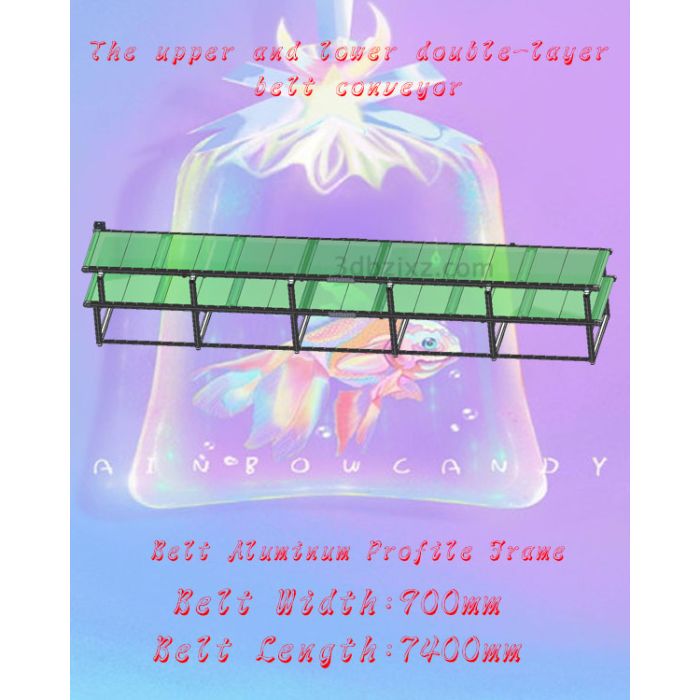

beltconveyor_a131_w900_l7400

- Stp samples download

- click to down

试用数据点击上方下载!

The upper and lower double-layer belt conveyor is an efficient material conveying equipment, which consists of two layers of conveyor belts and can complete more conveying tasks in the same space. The following is a detailed introduction to the upper and lower double-layer belt conveyor:

1、 Definition and Working Principle

Definition: The upper and lower double-layer belt conveyor is a conveying equipment composed of two parallel conveyor belts, used to achieve simultaneous transportation of materials at different heights.

Working principle: According to the principle of friction, the conveyor belt is driven by the transmission drum, and the material moves together with the belt on the belt, thus achieving the transportation of the material. The upper and lower conveyor belts are driven by their respective transmission devices and can operate independently or synchronously.

2、 Characteristics and advantages

Efficiency: The upper and lower double-layer belt conveyor can simultaneously transport two layers of materials, doubling the conveying speed and effectively improving logistics efficiency.

Energy saving: By adopting advanced energy-saving technologies, power consumption can be significantly reduced.

High reliability: The conveyor is made of high-strength materials, which have high wear resistance, long service life, and low maintenance costs.

Strong adaptability: It can be customized according to different working environments and material characteristics, improving the adaptability of the equipment.

Space saving: By vertically stacking, floor space is saved, which is very suitable for places with limited height.

3、 Application scenarios

Logistics industry: Used for rapid sorting, handling, and storage of items in warehouses, distribution centers, and other locations.

Mining industry: Complete the transportation tasks of bulk materials such as ore and coal in mining operations, improve transportation efficiency, and reduce labor and material costs.

Port industry: plays an important role in ship loading and unloading operations, and can quickly and efficiently complete the loading and unloading of containerized cargo, bulk cargo, and other items.

Food processing: used for conveying raw materials and packaging finished products.

Chemical and Environmental Protection: Transporting chemical substances, waste materials, etc.

4、 Installation and maintenance

Installation: Start installing from the machine head, and then sequentially install the intermediate frame, tail frame, drive device, roller frame, and other components of each section. During the installation process, ensure that the centerline of the conveyor is in a straight line, all components are aligned with the centerline, and kept horizontal.

Maintenance: Regularly check whether the fasteners of the equipment are tightened, whether there is lubricating oil at the lubrication points, and whether the conveyor belt is worn or damaged. Timely clean up accumulated materials, replace worn parts, and maintain equipment cleanliness and good operating condition.

5、 Development Trends

With the continuous development of the national economy and the rapid development of logistics, mining, ports and other fields, the market demand for upper and lower double-layer belt conveyors will continue to grow. In the future, manufacturers will continuously improve their technological level and produce more advanced, efficient, and stable products to meet market demand.

In summary, the upper and lower double-layer belt conveyor has the advantages of high efficiency, energy saving, reliability, strong adaptability, and space saving, and has broad application prospects in multiple industries.

上下双层皮带输送机是一种高效的物料输送设备,它由上下两层输送带组成,能够在相同的空间内完成更多的输送任务。以下是对上下双层皮带输送机的详细介绍:

一、定义与工作原理

- 定义:上下双层皮带输送机是一种由上下两层平行的输送带组成的输送设备,用于实现物料在不同高度上的同时输送。

- 工作原理:根据摩擦原理,由传动滚筒带动皮带运转,物料在皮带上与皮带一起运动,从而实现物料的输送。上层和下层输送带分别由各自的传动装置驱动,可以独立或同步运行。

二、特点与优势

- 高效性:上下双层皮带输送机能够同时输送两层物料,使得输送速度加倍,有效提高了物流效率。

- 节能性:采用先进的节能技术,可大幅降低动力消耗。

- 可靠性高:输送机采用高强度材料制造,具有较高的抗磨损性,使用寿命长,维护成本低。

- 适应性强:可根据不同的工作环境和物料特性进行定制化设计,提高了设备的适应性。

- 节省空间:通过垂直堆叠的方式节省地面空间,非常适合高度有限的场所。

三、应用场景

- 物流行业:在仓库、配送中心等场所,用于快速分拣、搬运和存储物品。

- 矿山行业:在采矿作业中完成矿石、煤炭等大宗物料的输送任务,提高运输效率,减少人力物力成本。

- 港口行业:在船舶装卸作业中起到重要作用,可以快速、高效地完成箱货、散货等物品的装卸。

- 食品加工:用于原料的输送和成品的分装。

- 化工与环保:输送化学物质、废料等。

四、安装与维护

- 安装:从机头开始安装,然后顺次安装各节中间架、尾架以及驱动装置、托辊架等部件。安装过程中要确保输送机的中心线在直线上,各部件对准中心线,并保持水平。

- 维护:定期检查设备各紧固件是否紧固、润滑点是否有润滑油、输送带是否磨损或损坏等。及时清理积料、更换磨损部件,保持设备清洁和良好运行状态。

五、发展趋势

随着国家经济的不断发展和物流、矿山、港口等领域的快速发展,上下双层皮带输送机的市场需求将持续增长。未来,制造商将不断提高技术水平,生产更加先进、高效、稳定的产品,以满足市场需求。

综上所述,上下双层皮带输送机具有高效、节能、可靠、适应性强和节省空间等优点,在多个行业中有着广泛的应用前景。