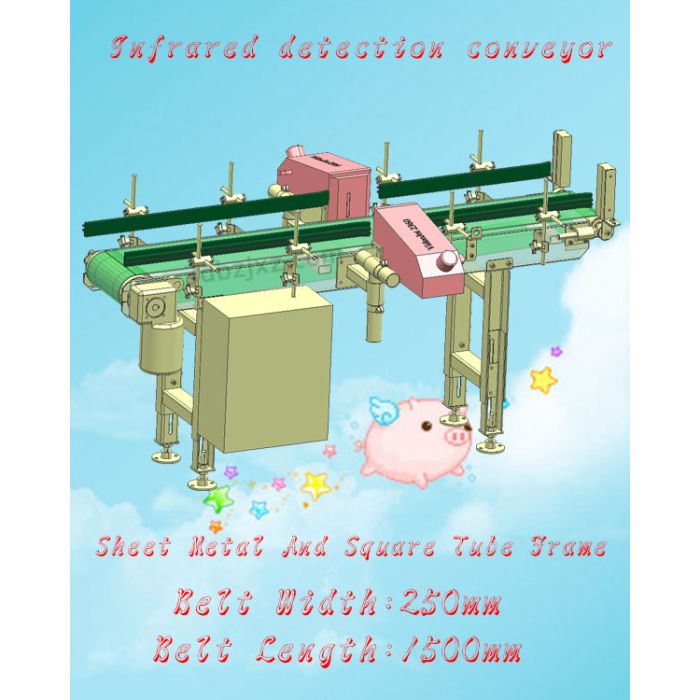

beltconveyor_091_w250_h1500

- Stp samples download

- click to down

试用数据点击上方下载!

Infrared detection conveyor mainly uses infrared sensors for material detection. The working principle is roughly as follows:

When the material passes through the conveyor, the infrared sensor emits infrared radiation and receives the reflected signal. Based on the changes in the strength of the reflected signal, the sensor can accurately determine the presence, position, and status of the material, thereby achieving precise control of the material. Specifically, infrared sensors have high sensitivity and precision, which can accurately detect the presence and status of materials, avoiding misjudgment and missed detection.

Infrared detection conveyor has multiple advantages, including but not limited to:

High precision: capable of accurately detecting the position and status of materials, improving the automation level and production efficiency of the production line.

Non contact detection: No direct contact with the material is required, reducing damage and pollution to the material.

Real time capability: It can monitor changes in materials in real-time and provide timely feedback to the control system, ensuring the stability and controllability of the production process.

Strong adaptability: not affected by factors such as material color and shape, suitable for testing various types of materials.

In addition, infrared detection conveyors have a wide range of applications in the field of industrial automation, such as production line automation, warehousing and logistics. In the production line, it can monitor the position and status of materials in real time, ensuring that materials are transported according to the preset process; In the field of warehousing and logistics, it can achieve rapid sorting and transportation of goods, reduce manual operations, and improve logistics efficiency.

Overall, infrared detection conveyors play an important role in the field of industrial automation due to their high precision, non-contact detection, real-time performance, and strong adaptability.

红外线检测输送机主要利用红外线传感器进行物料检测。其工作原理大致如下:

当物料通过输送机时,红外线传感器会发射红外线并接收反射回来的信号。根据反射信号的强弱变化,传感器能够准确判断物料的存在、位置以及状态,从而实现对物料的精准控制。具体来说,红外线传感器具有高灵敏度和高精度特点,能够准确检测物料的存在和状态,避免误判和漏检。

红外线检测输送机具有多种优势,包括但不限于:

- 高精度:能够准确检测物料的位置和状态,提高生产线的自动化程度和生产效率。

- 非接触式检测:无需与物料直接接触,减少了对物料的损伤和污染。

- 实时性:能够实时监测物料的变化,及时反馈给控制系统,确保生产过程的稳定性和可控性。

- 适应性强:不受物料颜色、形状等因素的影响,适用于各种不同类型的物料检测。

此外,红外线检测输送机在工业自动化领域有着广泛的应用,如生产线自动化、仓储物流等。在生产线中,它能够实时监测物料的位置和状态,确保物料按照预设的流程进行传输;在仓储物流领域,它可以实现对货物的快速分拣和传输,减少人工操作,提高物流效率。

总的来说,红外线检测输送机凭借其高精度、非接触式检测、实时性和强适应性等优势,在工业自动化领域发挥着重要作用。