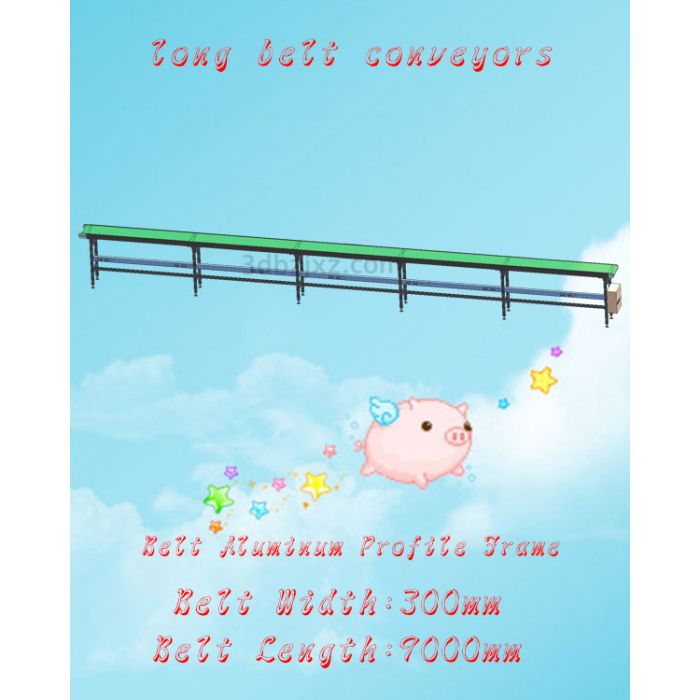

beltconveyor_w300_l9000

- Stp samples download

- click to down

试用数据点击上方下载!

The maximum length of aluminum profile conveyor belt is determined by multiple factors, including but not limited to the following:

Material properties: The material of the conveyor belt determines its physical strength and durability. The strength, elastic modulus, and other characteristics of materials can affect the performance of conveyor belts under long-term, high load operation. If the material strength is insufficient, the conveyor belt may experience fatigue, fracture, and other problems after prolonged use.

Manufacturing process: The manufacturing quality and process of conveyor belts also have a significant impact on their length. The handling of joints, uniformity of materials, and control of thickness all affect the overall performance and service life of conveyor belts. If the manufacturing process is poor, the conveyor belt may experience early damage.

Supporting structure: The supporting structure of the conveyor belt (such as rollers, drums, etc.) needs to be able to withstand the weight of the conveyor belt and the materials it carries. The strength and stability of the supporting structure determine the maximum length of the conveyor belt that can operate safely and effectively.

Drive system: The drive system of the conveyor belt (such as motors, reducers, etc.) needs to be able to provide sufficient driving force to overcome the frictional resistance and material weight resistance generated during the operation of the conveyor belt. If the power of the drive system is insufficient, the conveyor belt may not operate normally or may experience problems such as slipping and wear.

Application scenario: The application scenario of the conveyor belt is also one of the key factors determining its length. For example, in situations where frequent turns, climbing, or crossing complex terrain are required, the length of the conveyor belt may be limited. In addition, the length of the conveyor belt also needs to consider factors such as installation space, maintenance convenience, and cost.

In summary, the maximum length of aluminum profile conveyor belts is determined by multiple factors such as material properties, manufacturing processes, support structures, drive systems, and application scenarios. Therefore, when determining the length of the conveyor belt, it is necessary to comprehensively consider these factors and conduct detailed calculations and evaluations. If a longer conveyor belt is needed, it is recommended to consult a professional conveyor belt manufacturer or designer for more accurate and reliable advice.

铝型材输送带的最大长度是由多个因素综合决定的,这些因素包括但不限于以下几点:

-

材料特性:输送带的材料决定了其物理强度和耐久性。材料的强度、弹性模量等特性会影响输送带在长时间、高负荷运行下的表现。如果材料强度不足,输送带在长时间使用后可能会出现疲劳、断裂等问题。

-

制造工艺:输送带的制造质量和工艺对其长度也有重要影响。接头的处理、材料的均匀性、厚度的控制等都会影响到输送带的整体性能和使用寿命。如果制造工艺不佳,输送带可能会出现早期损坏。

-

支撑结构:输送带的支撑结构(如托辊、滚筒等)需要能够承受输送带及其承载物料的重量。支撑结构的强度和稳定性决定了输送带可以安全、有效地运行的最大长度。

-

驱动系统:输送带的驱动系统(如电机、减速器等)需要能够提供足够的驱动力来克服输送带运行时的摩擦阻力和物料重量所产生的阻力。如果驱动系统的功率不足,输送带可能无法正常运行,或者会出现打滑、磨损等问题。

-

应用场景:输送带的应用场景也是决定其长度的关键因素之一。例如,在需要频繁转弯、爬坡或穿越复杂地形的场合,输送带的长度可能会受到限制。此外,输送带的长度还需要考虑安装空间、维护便利性以及成本等因素。

综上所述,铝型材输送带的最大长度是由材料特性、制造工艺、支撑结构、驱动系统和应用场景等多个因素共同决定的。因此,在确定输送带长度时,需要综合考虑这些因素,并进行详细的计算和评估。如果需要更长的输送带,建议咨询专业的输送带制造商或设计师,以获取更准确和可靠的建议。