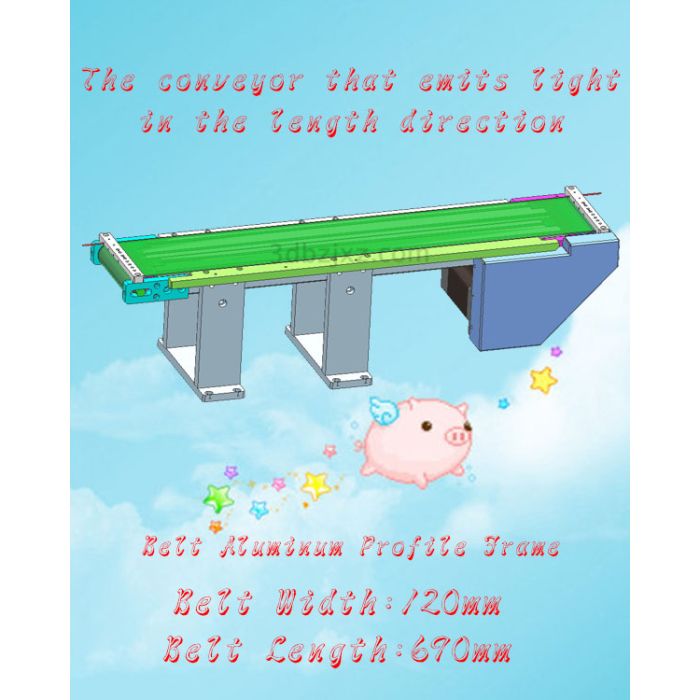

beltconveyor_w120_l690

- Stp samples download

- click to down

试用数据点击上方下载!

The conveyor that emits light in the length direction is a device that combines photoelectric detection technology with conveying function, and it has a wide range of applications in the field of industrial automation. The following is a detailed analysis of this device:

1、 Definition and Principle

A conveyor that emits light in the length direction, as the name suggests, is equipped with a photoelectric sensor along the length direction of the conveyor. The photoelectric sensor consists of a transmitter and a receiver, which are installed on both sides of the conveyor to form a photoelectric barrier. When an object passes through this barrier, it will block the light and trigger the signal output of the sensor. By detecting changes in this signal, accurate measurement and positioning of object length, position, and other information can be achieved.

2、 Main features

High precision measurement: The photoelectric sensor has the characteristics of high precision and high sensitivity, which can achieve accurate measurement of object length.

Non contact detection: Due to the use of photoelectric principles for detection, there is no need for direct contact with the object being measured, avoiding wear and error caused by contact.

Strong adaptability: The photoelectric sensor can adapt to the detection needs of objects of different shapes, sizes, and materials.

Easy to integrate: This conveyor can be easily integrated with other automation equipment and systems, achieving seamless integration with automated production lines.

3、 Application Fields

Conveyors that emit light along the length direction are widely used in various industrial automation scenarios that require precise measurement and positioning of objects, such as:

Logistics transportation: In logistics warehouses, this type of conveyor can be used for precise measurement and positioning of goods, achieving automatic sorting and packaging of goods.

Manufacturing: On the production line, this type of conveyor can be used for precise measurement and positioning of components, ensuring product quality and production efficiency.

Packaging industry: In the packaging process, this type of conveyor can be used for precise measurement and positioning of packaging materials, achieving automation and standardization of packaging.

4、 Technological development trends

With the continuous development of industrial automation technology, the length direction of the photoelectric conveyor is also constantly improving and perfecting. In the future, this type of device may develop in the following directions:

Intelligence: By integrating advanced sensors and control systems, intelligent operation and adaptive adjustment of equipment can be achieved.

Networking: connect equipment to the Internet through the Internet of Things technology to achieve remote monitoring and management.

Modularization: Adopting a modular design, it facilitates users to flexibly configure and expand according to their actual needs.

High precision: Continuously improving the accuracy and stability of sensors to meet higher precision measurement and positioning requirements.

In summary, the conveyor for reflecting light in the length direction is an automated conveying equipment with high precision, non-contact detection, and strong adaptability. It has broad application prospects and development potential in the field of industrial automation.

长度方向对射光电的输送机是一种结合了光电检测技术与输送功能的设备,它在工业自动化领域中具有广泛的应用。以下是对这种设备的详细解析:

一、定义与原理

长度方向对射光电的输送机,顾名思义,是在输送机的长度方向上设置了对射光电传感器。对射光电传感器由发射器和接收器组成,它们分别安装在输送机的两侧,形成一道光电屏障。当物体通过这道屏障时,会遮断光线,从而触发传感器的信号输出。通过检测这个信号的变化,可以实现对物体长度、位置等信息的精确测量和定位。

二、主要特点

- 高精度测量:对射光电传感器具有高精度和高灵敏度的特点,能够实现对物体长度的精确测量。

- 非接触式检测:由于采用光电原理进行检测,因此无需与被测物体直接接触,避免了因接触而产生的磨损和误差。

- 适应性强:对射光电传感器可以适应不同形状、尺寸和材质的物体检测需求。

- 易于集成:这种输送机可以方便地与其他自动化设备和系统进行集成,实现自动化生产线的无缝对接。

三、应用领域

长度方向对射光电的输送机广泛应用于各种需要精确测量和定位物体的工业自动化场景中,如:

- 物流输送:在物流仓库中,这种输送机可以用于对货物的精确测量和定位,实现货物的自动分拣和打包。

- 生产制造:在生产线上,这种输送机可以用于对零部件的精确测量和定位,确保产品的质量和生产效率。

- 包装行业:在包装过程中,这种输送机可以用于对包装物的精确测量和定位,实现包装的自动化和标准化。

四、技术发展趋势

随着工业自动化技术的不断发展,长度方向对射光电的输送机也在不断进步和完善。未来,这种设备可能会朝着以下几个方向发展:

- 智能化:通过集成先进的传感器和控制系统,实现设备的智能化运行和自适应调整。

- 网络化:通过物联网技术将设备连接到互联网上,实现远程监控和管理。

- 模块化:采用模块化设计,方便用户根据实际需求进行灵活配置和扩展。

- 高精度化:不断提高传感器的精度和稳定性,满足更高精度的测量和定位需求。

综上所述,长度方向对射光电的输送机是一种具有高精度、非接触式检测、适应性强等特点的自动化输送设备。它在工业自动化领域中具有广泛的应用前景和发展潜力。