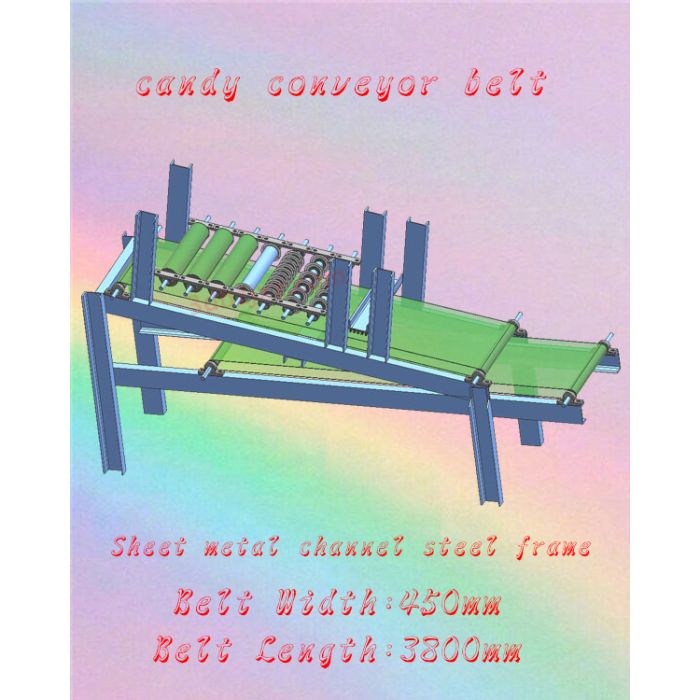

beltconveyor_w450_l3800

- Stp samples download

- click to down

试用数据点击上方下载!

The candy conveyor belt needs to pay attention to the following aspects in its design to ensure that it meets the specific needs of candy production and food safety standards:

1、 Material selection

Chemical corrosion resistance: Due to the high concentration of acidic and alkaline components in candy, it is easy to cause corrosion to conveyor belts made of ordinary materials. Therefore, materials resistant to chemical corrosion such as stainless steel, PTFE, PVDF, etc. should be preferred.

Food grade requirements: The conveyor belt must comply with relevant food safety regulations such as FDA and EU, ensuring that it is non-toxic, odorless, and will not contaminate candy products.

Wear resistance: Considering that hard impurities such as sugarcane bagasse and sand may accelerate the wear of the conveyor belt, high wear resistant materials such as reinforced rubber and reinforced polyurethane (PU) should be selected to extend the service life, reduce replacement frequency and maintenance costs.

2、 Structural Design

Cleanliness: The surface of the conveyor belt should be designed to be smooth and easy to clean to reduce the chance of microbial growth and ensure product purity. At the same time, a mechanism that is easy to disassemble and assemble should be designed for rapid and thorough disinfection, reducing downtime.

Heat resistance: Due to the high temperature and steam environment during the sugar making process, the selected material must have excellent heat resistance and be able to withstand extreme conditions for a long time without deformation or softening. At the same time, certain processes may require rapid cooling, so attention should also be paid to low-temperature resistance.

Protective devices: Reasonable protective devices and safety facilities should be set up to reduce the occurrence of accidents and ensure the safety of workers. For example, protective barriers can be installed on both sides of the conveyor belt to prevent accidental contact by personnel.

3、 Layout planning

Process optimization: Arrange the conveyor belt at a suitable position in the candy processing flow to ensure smooth transfer of candy from one process to the next, reduce waiting time and material handling time in the production process, and improve production efficiency.

Space utilization: Considering the limited space in candy processing workshops, the layout of conveyor belts should make full use of space as much as possible to ensure a reasonable layout between production equipment and work areas. Avoid crowded and chaotic situations, and improve production and work efficiency.

Flexible and Adjustable: Due to the constantly changing demands of the candy processing industry, the layout of conveyor belts should have a certain degree of flexibility and adjustability. When designing, possible future production expansion or production line adjustments should be considered in order to adjust the layout of the conveyor belt in a timely manner to meet different production needs.

4、 Equipment matching and collaboration

Matching with other equipment: Conveyor belts usually need to be used in conjunction with other production equipment, such as packaging machines, weighing machines, etc. When designing the layout of conveyor belts, consideration should be given to the coordination and collaboration with other equipment to ensure the smooth operation and efficient production of the entire production line.

Automated control: An automated control system can be introduced to achieve automatic start stop, speed adjustment, and other functions of the conveyor belt, improving the automation level of the production line.

5、 Energy conservation and environmental protection

Energy saving equipment: When designing conveyor belts, the principle of energy conservation and environmental protection should be considered. Energy saving conveyor belt equipment should be selected, and energy should be used reasonably to reduce resource waste and environmental pollution.

Renewable materials: In response to the green manufacturing initiative, priority is given to conveyor belts made from recycled or recyclable materials to reduce carbon footprint and demonstrate corporate social responsibility.

In summary, the design of candy conveyor belts needs to comprehensively consider multiple aspects such as material selection, structural design, layout planning, equipment matching and coordination, as well as energy conservation and environmental protection, to ensure that they meet the specific needs of candy production and food safety standards.

糖果输送带在设计上需要注意以下几个方面,以确保其满足糖果生产的特定需求和食品安全标准:

一、材质选择

- 耐化学品腐蚀:由于糖果中可能含有较高浓度的酸碱成分,容易对普通材质的输送带造成腐蚀。因此,应优选不锈钢、特氟龙(PTFE)、PVDF等耐化学品腐蚀的材质。

- 食品级要求:输送带必须符合FDA、EU等相关食品安全法规,确保无毒、无味,不会对糖果产品造成污染。

- 耐磨性:考虑到甘蔗渣、砂石等硬质杂质可能导致输送带磨损加速,应选用高耐磨性的材质,如加强型橡胶、强化聚氨酯(PU)等,以延长使用寿命,减少更换频率和维护成本。

二、结构设计

- 易清洁性:输送带表面应设计得平滑,易于清洁,以减少微生物滋生的机会,保证产品纯度。同时,应设计有易于拆卸和组装的机制,以便快速彻底消毒,减少停机时间。

- 耐热性:由于制糖过程中存在高温、蒸汽环境,所选材料须具备优秀的耐热性,能够在长时间暴露于极端条件下也不发生变形、软化。同时,某些环节可能需要快速冷却,所以也需要关注低温抵抗能力。

- 防护装置:应合理设置防护装置和安全设施,以减少事故的发生,保障工作人员的安全。例如,输送带两侧可设置防护栏,防止人员意外接触。

三、布局规划

- 流程优化:将输送带布置在糖果加工流程的合适位置,确保糖果从一个工序顺利地传送到下一个工序,减少生产过程中的等待时间和物料处理时间,提高生产效率。

- 空间利用:考虑到糖果加工车间通常空间有限的情况,输送带的布局应尽可能充分利用空间,确保生产设备和工作区域之间的合理布局。避免出现拥挤、混乱的情况,提高生产效率和工作效率。

- 灵活可调:由于糖果加工行业的需求常常会发生变化,因此输送带的布局应具有一定的灵活性和可调性。设计时应考虑到未来可能的生产扩张或生产线调整,以便及时调整输送带的布局,满足不同生产需求。

四、设备配套与协同

- 与其他设备配套:输送带通常需要与其他生产设备进行配合使用,如包装机、称重机等。在设计输送带布局时,要考虑到与其他设备之间的配套和协同工作,确保整个生产线的顺畅运行和高效生产。

- 自动化控制:可以引入自动化控制系统,实现输送带的自动启停、速度调节等功能,提高生产线的自动化水平。

五、节能环保

- 节能型设备:在设计输送带时,应考虑到节能环保的原则,选择节能型输送带设备,并合理利用能源,减少资源的浪费和环境的污染。

- 可再生材料:响应绿色制造倡议,优先选取再生或可回收材料制作的输送带,减少碳足迹,体现企业社会责任感。

综上所述,糖果输送带在设计上需要综合考虑材质选择、结构设计、布局规划、设备配套与协同以及节能环保等多个方面,以确保其满足糖果生产的特定需求和食品安全标准。