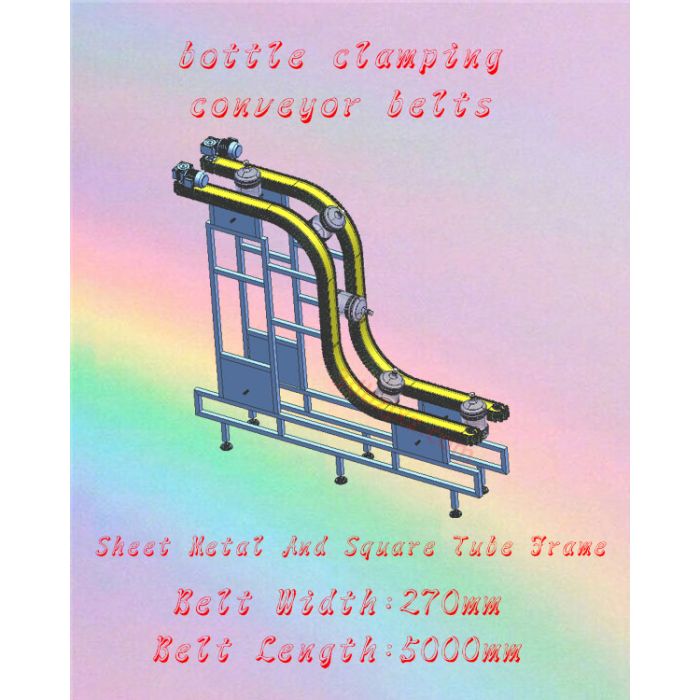

beltconveyor_w270_l5000

- Stp samples download

- click to down

试用数据点击上方下载!

There are significant differences in design and function between bottle clamping conveyor belts and ordinary conveyor belts to meet the needs of different material conveying. The following are the main differences between the two:

1、 Design Structure

Bottle clamp conveyor belt:

Specially designed for bottle shaped items, stable grasping and conveying of bottles are achieved through a clamping mechanism.

The clamping mechanism can be adjusted according to the shape and size of the bottle to ensure stable clamping and prevent it from falling off easily.

The common bottle clamp conveyor has two types: double clamp and side clamp, to adapt to bottles of different shapes and sizes.

Ordinary conveyor belt:

There are various structures, including edge wrapped, open edge, middle ladder, edge ladder, and other different types.

Usually made of materials such as canvas or rubber, it is used to transport non corrosive and non spiky block, granular, and powder materials, such as coal, coke, sand and gravel, cement, and other bulk or packaged items.

2、 Functional Features

Bottle clamp conveyor belt:

High conveying efficiency: Advanced clamping technology and driving system are adopted to achieve fast and stable transportation of bottles.

Strong adaptability: able to meet the transportation needs of various shaped bottles and bottles of different sizes, providing strong support for the flexibility of the production line.

High level of intelligence: Real time monitoring and intelligent control of the conveying process are achieved through control components such as PLC and sensors.

Protecting bottles: The clamping mechanism can prevent bottles from tipping or colliding during transportation, reducing bottle damage.

Ordinary conveyor belt:

Wide conveying range: suitable for conveying various materials such as coal, coke, sand and gravel.

Simple structure: The design is relatively simple, easy to install, disassemble, and maintain.

Low cost: Due to the relatively simple materials and structure, the manufacturing cost is relatively low.

3、 Application scenarios

Bottle clamp conveyor belt:

Widely used in industries such as food, beverage, pharmaceuticals, cosmetics, etc., for automated transportation of bottle shaped items.

In these industries, bottle clamping conveyor belts can achieve seamless integration with filling machines, labeling machines, packing machines and other equipment, forming a complete automated production line.

Ordinary conveyor belt:

Suitable for conveying various materials, such as coal, ore, building materials and other industries' production lines.

When conveying non corrosive, non spiky block, granular, and powder materials at room temperature, ordinary conveyor belts are a commonly used choice.

In summary, there are significant differences between bottle clamping conveyor belts and ordinary conveyor belts in terms of design structure, functional characteristics, and application scenarios. The choice of conveyor belt depends on factors such as the specific material type, conveying requirements, and production line layout.

夹瓶输送带与普通输送带在设计和功能上存在着显著的差异,以满足不同物料输送的需求。以下是两者的主要区别:

一、设计结构

-

夹瓶输送带:

- 专为瓶状物品设计,通过夹持机构实现对瓶子的稳定抓取和输送。

- 夹持机构可根据瓶子的形状、大小进行调整,确保夹持稳定,不易掉落。

- 常见的夹瓶输送带有对夹式和侧夹式两种,以适应不同形状和尺寸的瓶子。

-

普通输送带:

- 结构多样,包括包边式、开边式、中梯型、边梯型等不同结构。

- 通常由帆布或橡胶等材料制成,用于输送非腐蚀性的无尖刺的块状、粒状、粉末的多种物料,如煤炭、焦炭、砂石、水泥等散物或成件物品。

二、功能特点

-

夹瓶输送带:

- 输送效率高:采用先进的夹持技术和驱动系统,实现瓶子的快速、稳定输送。

- 适应性强:能够应对各种异型瓶、异尺寸瓶的输送需求,为生产线的灵活性提供了有力保障。

- 智能化水平高:通过PLC和传感器等控制元件,实现输送过程的实时监测和智能控制。

- 保护瓶子:夹持机构能够避免瓶子在输送过程中的倾倒、碰撞,减少瓶子损伤。

-

普通输送带:

- 输送范围广:适用于多种物料的输送,如煤炭、焦炭、砂石等。

- 结构简单:设计相对简单,易于安装、拆卸和维护。

- 成本低:由于材料和结构的相对简单,制造成本较低。

三、应用场景

-

夹瓶输送带:

- 广泛应用于食品、饮料、制药、化妆品等行业,用于瓶状物品的自动化输送。

- 在这些行业中,夹瓶输送带能够实现与灌装机、贴标机、装箱机等设备的无缝对接,形成完整的自动化生产线。

-

普通输送带:

- 适用于各种物料的输送,如煤炭、矿石、建材等行业的生产线。

- 在常温下输送非腐蚀性的无尖刺块状、粒状、粉末物料时,普通输送带是常用的选择。

综上所述,夹瓶输送带和普通输送带在设计结构、功能特点和应用场景等方面存在显著差异。选择哪种输送带取决于具体的物料类型、输送需求和生产线布局等因素。