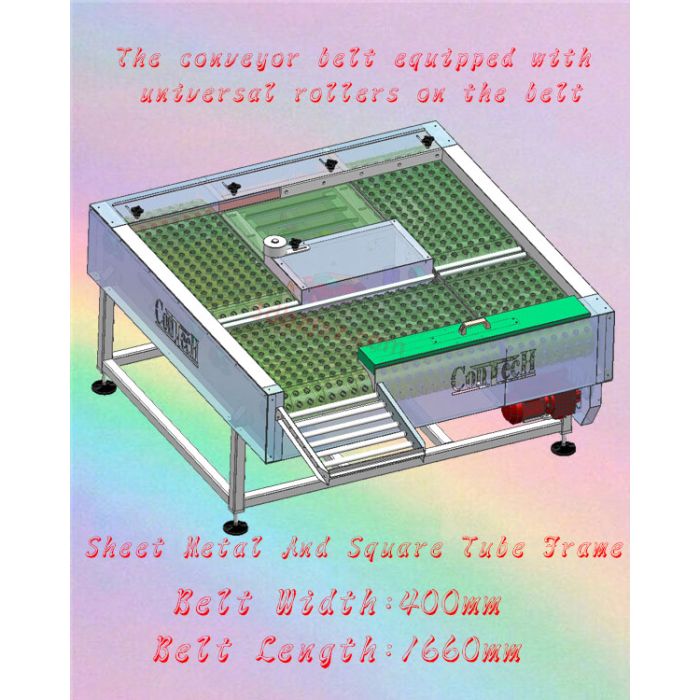

beltconveyor_w400_l1600

- Stp samples download

- click to down

试用数据点击上方下载!

The conveyor belt equipped with universal rollers on the belt is a special type of conveying equipment, and its manufacturing process involves multiple links and steps. The following is a general description of the manufacturing process of this type of conveyor belt:

1、 Raw material preparation

Conveyor belt material: Conveyor belts are usually made of rubber, PVC, or other synthetic materials, which have good wear resistance, corrosion resistance, and tensile strength.

Universal rollers: Universal rollers are usually made of metal or plastic and have the characteristics of flexible rotation and strong load-bearing capacity. They are evenly installed below the conveyor belt to support and guide the movement of the conveyor belt.

2、 Manufacturing process

Mixing and Rolling: Adding rubber or other synthetic materials into a mixing machine for uniform distribution of various components. Then, the mixed materials are pressed into the desired semi-finished film product through a rolling mill.

Molding and vulcanization: The semi-finished film obtained by rolling is molded into the desired shape of the conveyor belt through a molding mechanism according to the specifications. Next, the formed conveyor belt is vulcanized to improve its strength and durability.

Install universal rollers: Install universal rollers below the conveyor belt according to the predetermined spacing and arrangement. These rollers are fixed on the conveyor frame through brackets or pallets to ensure that they can rotate smoothly and support the conveyor belt.

Quality inspection and packaging: Conduct quality inspection on the manufactured conveyor belt, including checking its appearance, size, strength and other performance indicators. Qualified conveyor belts will be packaged for transportation and storage.

3、 Special processes and requirements

Roller selection and installation: The selection and installation of universal rollers are crucial for the performance of conveyor belts. Rollers should have appropriate hardness, wear resistance, and load-bearing capacity to ensure smooth and efficient operation of the conveyor belt. At the same time, the installation position and spacing of the rollers also need to be adjusted according to specific conveying requirements and material characteristics.

Conveyor belt design: The design of the conveyor belt needs to consider factors such as material type, conveying speed, and conveying distance. For example, for fragile or viscous materials, special conveyor belt materials and structures may be required to reduce damage and adhesion to the materials.

Safety and maintenance: During the manufacturing and use of conveyor belts, it is necessary to strictly comply with relevant safety regulations and standards. In addition, it is necessary to regularly maintain and upkeep the conveyor belt to ensure its long-term stable operation.

4、 Application and advantages

Conveyor belts equipped with universal rollers are widely used in various industrial fields, such as food processing, mining, logistics and warehousing. They have the advantages of high conveying efficiency, strong carrying capacity, smooth operation, and easy maintenance. Meanwhile, due to the presence of universal rollers, the conveyor belt can reduce damage and adhesion to materials during the conveying process, thereby improving the conveying quality.

In summary, the manufacturing process of conveyor belts equipped with universal rollers involves multiple links and steps, requiring strict control over raw material quality, manufacturing processes, and special requirements. Through reasonable design and manufacturing, the conveyor belt can ensure excellent performance and long-term stable operation.

皮带上装有万向滚子的输送带是一种特殊的输送设备,其制造过程涉及多个环节和步骤。以下是关于这种输送带制造过程的一般性描述:

一、原材料准备

- 输送带材料:输送带通常由橡胶、PVC或其他合成材料制成,这些材料具有良好的耐磨性、耐腐蚀性和抗拉强度。

- 万向滚子:万向滚子通常由金属或塑料制成,具有旋转灵活、承载能力强等特点。它们被均匀地安装在输送带的下方,以支撑和引导输送带的运动。

二、制造工艺

- 密炼与压延:将橡胶或其他合成材料加入密炼机中进行混合,以确保各种成分均匀分布。然后,将混合好的材料通过压延机压制成所需的胶片半成品。

- 成型与硫化:将压延得到的胶片半成品根据规格要求,通过成型机制成所需的输送带形状。接着,将成型后的输送带进行硫化处理,以提高其强度和耐久性。

- 安装万向滚子:在输送带的下方,按照预定的间距和排列方式安装万向滚子。这些滚子通过支架或托板固定在输送架上,以确保它们能够平稳地旋转和支撑输送带。

- 质量检测与包装:对制造完成的输送带进行质量检测,包括检查其外观、尺寸、强度等性能指标。合格的输送带将被包装起来,以便运输和存储。

三、特殊工艺与要求

- 滚子选择与安装:万向滚子的选择和安装对于输送带的性能至关重要。滚子应具有适当的硬度、耐磨性和承载能力,以确保输送带能够平稳、高效地运行。同时,滚子的安装位置和间距也需要根据具体的输送要求和物料特性进行调整。

- 输送带设计:输送带的设计需要考虑到物料类型、输送速度、输送距离等因素。例如,对于易碎或粘性物料,可能需要采用特殊的输送带材料和结构,以减少对物料的损伤和粘附。

- 安全与维护:在输送带的制造和使用过程中,需要严格遵守相关的安全规范和标准。此外,还需要定期对输送带进行维护和保养,以确保其长期稳定运行。

四、应用与优势

皮带上装有万向滚子的输送带广泛应用于各种工业领域,如食品加工、矿山开采、物流仓储等。它们具有输送效率高、承载能力强、运行平稳、维护方便等优点。同时,由于万向滚子的存在,输送带在输送过程中能够减少对物料的损伤和粘附,提高输送质量。

综上所述,皮带上装有万向滚子的输送带的制造过程涉及多个环节和步骤,需要严格控制原材料质量、制造工艺和特殊要求等方面。通过合理的设计和制造,可以确保输送带具有优异的性能和长期稳定的运行效果。