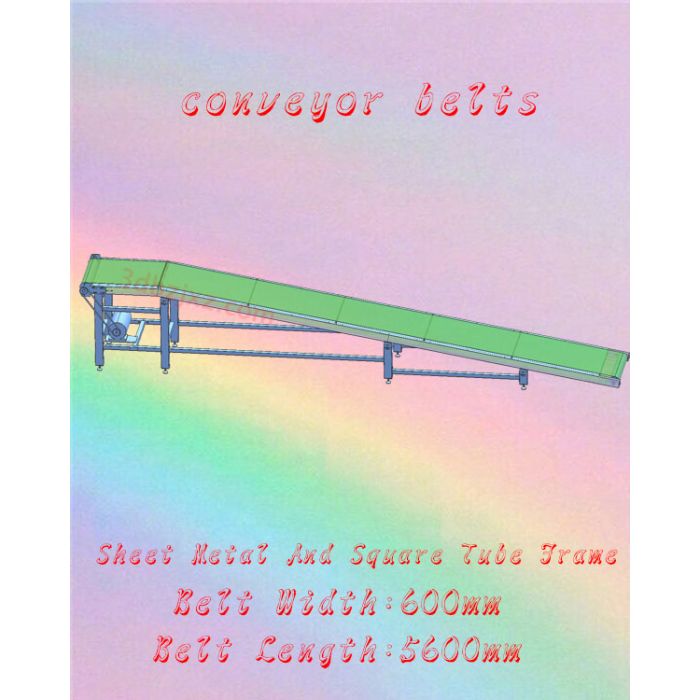

beltconveyor_w600_l5600

- Stp samples download

- click to down

试用数据点击上方下载!

Belt conveyor belts play a crucial role in modern industrial production, and their highlights are mainly reflected in the following aspects:

1、 Efficient and stable conveying capacity

Belt conveyor belts can achieve continuous and efficient material transportation, suitable for the transportation of various materials and products. Whether it is solid particles, powders, or finished goods, they can be efficiently and stably transported through belt conveyors. This has made belt conveyors widely used in many industries such as mining, ports, building materials, and chemical engineering.

2、 Flexible and diverse adaptability

Terrain and spatial limitations: Belt conveyors can adapt to different terrains and spatial limitations, and can horizontally, obliquely, and even vertically lift materials. By designing the layout of the conveyor reasonably, space can be fully utilized to meet the needs of complex production processes.

Material characteristics: The belt conveyor can adapt to different material particle sizes and conveying capacity requirements. By adjusting parameters such as belt width and speed, it can flexibly meet various production conditions.

3、 Durable and low maintenance cost

Belt conveyors have high durability and can withstand long-term continuous use and harsh working environments. High quality materials and sophisticated manufacturing processes ensure the stability and lifespan of the conveyor belt, reducing maintenance costs and replacement frequency.

4、 Energy saving, environmentally friendly, safe and reliable

Energy saving and environmental protection: Belt conveyors have low noise and low energy consumption during operation, meeting the requirements of energy saving and environmental protection. Compared with other conveying methods, belt conveyors have a higher energy utilization rate and can effectively reduce production costs.

Safety protection: Belt conveyors are usually equipped with various safety protection devices, such as anti-skid protection, coal stacking protection, anti deviation devices, etc., to ensure the safety and reliability of the conveying process.

5、 Easy to implement automated control

Belt conveyor belts can be used in conjunction with other automation equipment to achieve automated control of the production process. For example, by connecting with sensors, PLC control systems, etc., real-time monitoring and adjustment of parameters such as material flow rate, conveying speed, and belt tension can be achieved, improving production efficiency and quality. The improvement of automation also reduces manual operations, lowers labor intensity, and enhances work safety.

6、 Easy installation and maintenance

The installation of belt conveyor belt is simple and saves the width space of the belt conveyor. Meanwhile, its structure is simple and easy to maintain and upkeep. Regular inspection, cleaning, and lubrication of conveyor belts can extend their service life and maintain their good operating condition.

In summary, belt conveyors have become an indispensable logistics tool in modern industrial production due to their efficient and stable conveying capacity, flexible and diverse adaptability, durability and low maintenance costs, energy conservation, environmental protection, safety and reliability, easy implementation of automation control, and easy installation and maintenance.

皮带式输送带在现代工业生产中扮演着至关重要的角色,其亮点主要体现在以下几个方面:

一、高效稳定的输送能力

皮带式输送带能够实现连续、高效的物料输送,适用于各种物料和产品的运输,无论是固体颗粒、粉末还是成品货物,都可以通过皮带输送带进行高效、稳定的运输。这使得皮带输送带在矿山、港口、建材、化工等众多行业中得到了广泛应用。

二、灵活多样的适应性

- 地形和空间限制:皮带式输送带能够适应不同的地形和空间限制,可以水平输送、倾斜输送甚至垂直提升物料。通过合理设计输送机的布置形式,可以充分利用空间,满足复杂生产流程的需求。

- 物料特性:皮带输送带可适应不同的物料粒度和输送量要求,通过调整皮带宽度、速度等参数,能够灵活地满足各种生产工况。

三、耐用且维护成本低

皮带输送带具有较高的耐用性,能够承受长时间的连续使用和恶劣的工作环境。高品质的材料和精良的制造工艺保证了输送带的稳定性和寿命,降低了维护成本和更换频率。

四、节能环保且安全可靠

- 节能环保:皮带式输送带在运行过程中噪音低、能耗小,符合节能环保的要求。与其他输送方式相比,皮带输送机的能源利用率较高,能够有效降低生产成本。

- 安全保护:皮带输送机通常配备有各种安全保护装置,如防滑保护、堆煤保护、防跑偏装置等,确保了输送过程的安全可靠性。

五、易于实现自动化控制

皮带式输送带可以与其他自动化设备配合使用,实现生产过程的自动化控制。例如,通过与传感器、PLC控制系统等连接,可以实现对物料流量、输送速度、皮带张力等参数的实时监测和调节,提高生产效率和质量。自动化程度的提高还减少了人工操作,降低了劳动强度,提高了工作安全性。

六、安装与维护简便

皮带式输送带的安装简便,节省皮带机的宽度空间。同时,其结构简单,易于维护和保养。定期对输送带进行检查、清洁和润滑等保养工作,可以延长其使用寿命并保持其良好的运行状态。

综上所述,皮带式输送带以其高效稳定的输送能力、灵活多样的适应性、耐用且维护成本低、节能环保且安全可靠、易于实现自动化控制以及安装与维护简便等亮点,成为了现代工业生产中不可或缺的物流工具。